The Importance of Registration in Letterpress Printing

Registration is a cornerstone of high-quality letterpress printing. It's more than just getting things to line up; it's about achieving a unified, professional, and visually satisfying final product. For those new to the craft, understanding registration can seem daunting, but grasping the basics is crucial for anyone striving for excellence in letterpress.

What is Registration?

Simply put, registration refers to the precise alignment of multiple printed elements on a single sheet of paper. In letterpress, this often involves aligning multiple colors, different plates (e.g., text and an image), or even multiple passes of the same plate to build up density or texture. When registration is off, colors smear, images shift, and the overall impression is marred by a lack of precision. The mechanics of letterpress printing itself can be complex, and learning about understanding the parts of a letterpress is an excellent starting point for truly appreciating the intricacies of the process.

Why is Registration So Important in Letterpress?

Letterpress printing, with its tactile impression and often intricate designs, thrives on precision. The depth and beauty of the print are amplified when the individual elements are flawlessly aligned. Consider a multi-color design: if the colors don’t register correctly, the image becomes muddy and loses its intended impact. Even subtle misalignments can be noticeable and detract from the overall quality of the piece. This is particularly noticeable in complex designs where multiple passes with different inks and plates are required.

Beyond aesthetics, accurate registration demonstrates a commitment to craftsmanship. It reflects attention to detail and a deep understanding of the printing process. A perfectly registered print is a testament to the printer’s skill and dedication. Achieving this level of precision demands careful preparation and a methodical approach, often involving significant experimentation to optimize the entire process.

Understanding Registration Marks

Registration is achieved through the use of registration marks. These are small, typically cross-shaped, marks printed on the plate (or plates) that serve as visual guides for alignment. Before printing a color or element, a “key” or “registration plate” is printed containing these marks. Subsequent plates are then aligned precisely to these marks.

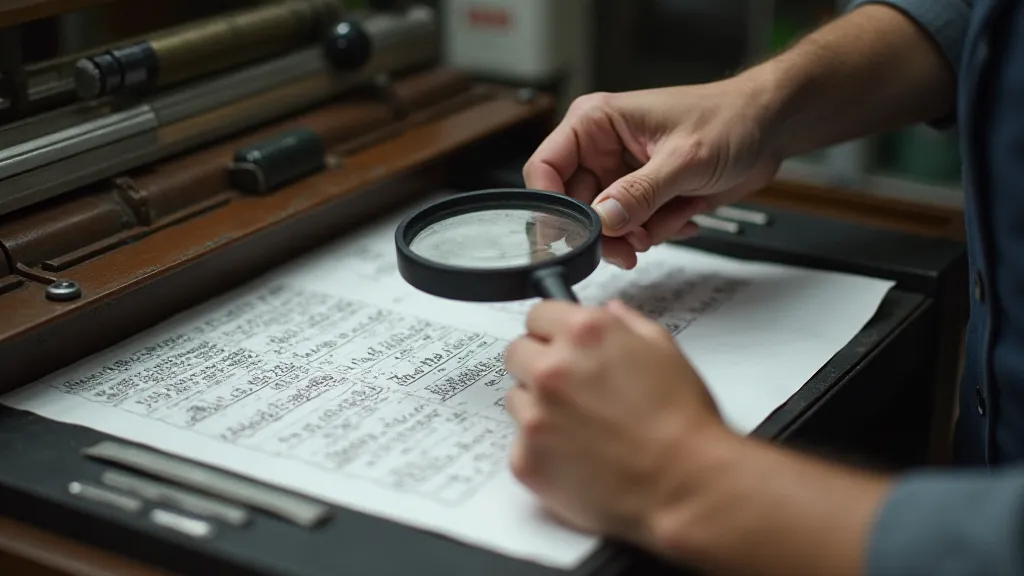

The process involves carefully observing these marks through a loupe or magnifying glass. Minute adjustments are made to the plate’s position until the registration marks line up perfectly. This is a meticulous process that requires a steady hand and a keen eye. The difficulty can be compounded by factors like paper thickness and ink consistency, making the initial registration process a critical step in achieving a final product of high quality.

Achieving Perfect Registration: Practical Tips

Here are a few key considerations for achieving excellent registration in letterpress:

- Stable Press Setup: Ensure your press is firmly secured and level. Any movement during printing will disrupt registration.

- Consistent Paper: Use paper of consistent thickness and moisture content. Variations in paper can cause shifting during printing.

- Careful Plate Mounting: Securely mount your plates to the press, ensuring they are properly positioned and locked in place.

- Fine-Tuning Ink: The consistency of your ink can affect registration. Experiment with different ink formulations to find what works best for your press and paper. Many letterpress enthusiasts find exploring ink and color mixing for letterpress a rewarding way to personalize their prints and fine-tune their registration process.

- Patient Observation: Don't rush the registration process. Take the time to carefully observe the registration marks and make incremental adjustments.

Common Registration Problems & Solutions

Even with careful attention, registration issues can arise. Some common problems include:

- Ghosting: A faint impression of a previously printed color. This often indicates excessive pressure or ink transfer. This can occur if the impression pressure is too high, or if the ink isn’t fully dry before the next pass.

- Smearing: Colors blending together due to inaccurate alignment or improper ink drying. Smearing is a frustrating problem, but carefully controlling ink consistency and ensuring adequate drying time are usually the keys to resolution.

- Shifting: Elements sliding out of alignment during printing. This can be caused by unstable paper or a loose press. A loose press can introduce unwanted vibrations, leading to shift, while variations in paper moisture can cause it to expand or contract.

- Double Impression: This presents as a slightly heavier or more pronounced impression of a specific color. This can result from the plate not being fully released from the paper after the initial impression.

- Incomplete Impression: The opposite of a double impression, incomplete impressions occur when the plate does not fully transfer ink to the paper.

Addressing these issues often involves a combination of adjustments to the press, ink, and printing technique. Experimentation and a keen eye are your best tools. The troubleshooting process itself can be complex, and exploring troubleshooting common letterpress printing problems can provide valuable insights and solutions.

Delving Deeper: Advanced Registration Techniques

Beyond the fundamentals, experienced letterpress printers often employ more sophisticated techniques. These might include utilizing a ‘lock ring’ to create an absolute reference point for registration, or creating registration guides directly on the press bed. While these are more involved, they can drastically improve accuracy, especially when printing intricate designs or long runs.

The Role of Press Maintenance

Regular maintenance of your letterpress equipment is crucial for consistent registration. This includes checking for any play or looseness in the moving parts, ensuring proper lubrication, and inspecting the platen for wear. A well-maintained press will run smoother, more accurately, and with less risk of registration issues.

Conclusion

Mastering registration is a cornerstone of letterpress excellence. While it requires patience and precision, the rewards are well worth the effort. With practice and attention to detail, you can consistently produce letterpress prints that are both beautiful and technically flawless. And remember, embracing the learning process, experimenting with different techniques, and considering simple DIY projects can be a great way to hone your skills and further appreciate the art form. So, embrace the challenge, hone your skills, and enjoy the satisfaction of creating truly exceptional letterpress pieces.